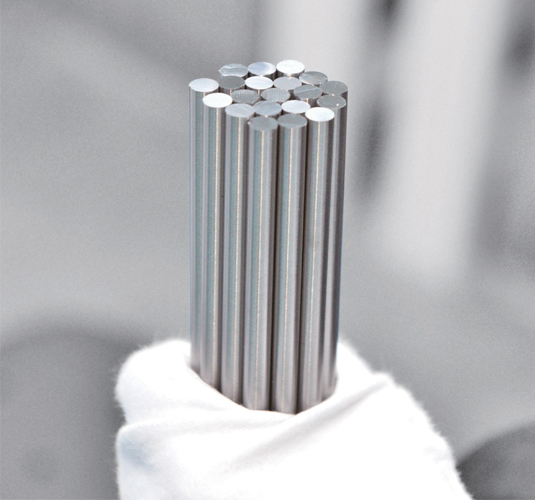

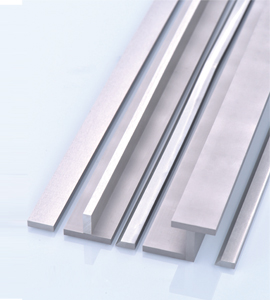

Cemented carbide rods are precision engineering stalwarts, known for their remarkable hardness, wear resistance, and adaptability. These rods, made of tungsten carbide particles bound together by a robust metal binder, form the basis for a wide range of cutting tools and wear-resistant components used in a variety of sectors. In this article, we look at the composition, qualities, uses, and benefits of cemented carbide rods, emphasizing their critical role in modern production.

Cemented carbide rods are predominantly made up of tungsten carbide (WC) particles, which range in weight from 70% to 94%, and are cemented together with a strong metal binder, often cobalt (Co) or nickel (Ni), which accounts for the remaining amount. The exact ratio of tungsten carbide to binder material determines the rods' mechanical characteristics, with more tungsten carbide concentration conferring better hardness and wear resistance. Advanced production methods such as powder metallurgy and sintering guarantee that tungsten carbide grains are evenly distributed throughout the binder matrix, resulting in a dense and homogenous structure.