Coolant rods are an essential component of contemporary machining operations, helping to optimize cutting performance, lengthen tool life, and improve surface smoothness. These unique tools, which are intended to supply accurate coolant straight to the cutting zone, provide several benefits in a variety of machining operations. This article investigates the functioning, benefits, uses, and considerations related with coolant rods, emphasizing their importance in obtaining improved machining outcomes.

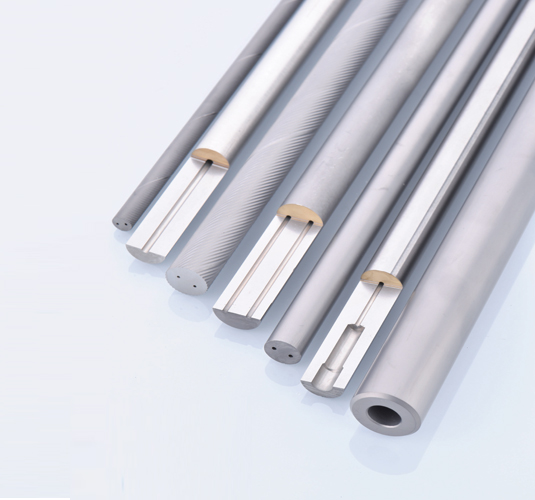

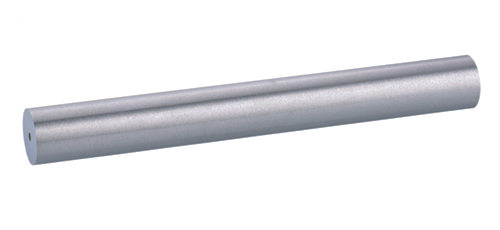

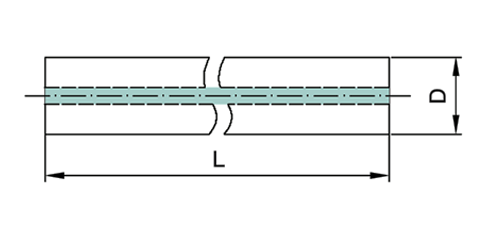

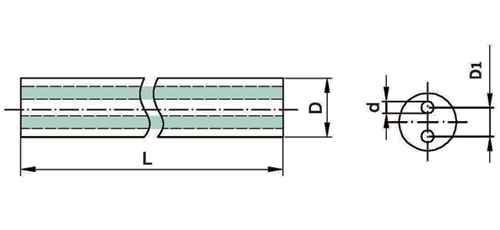

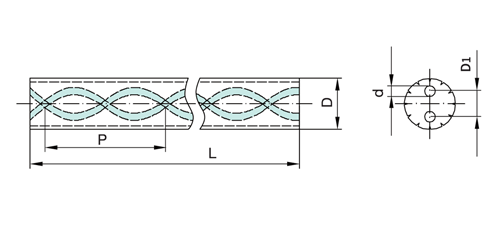

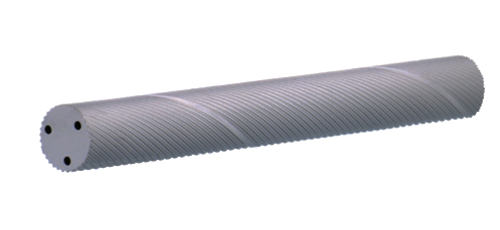

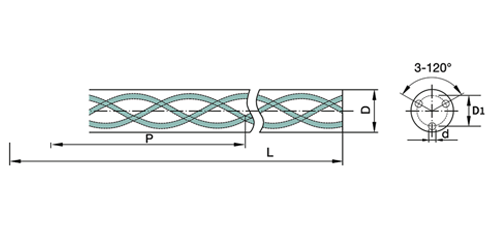

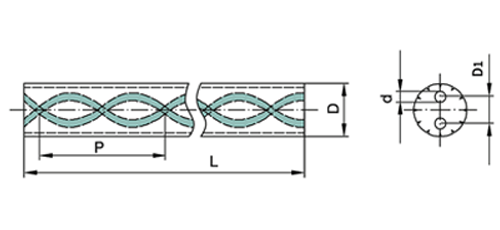

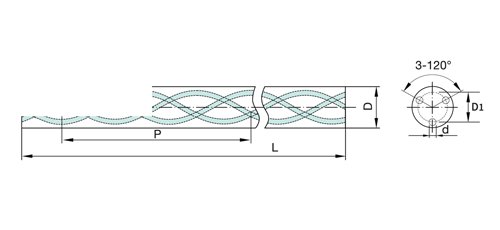

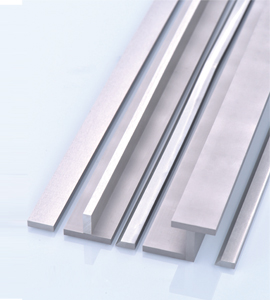

Coolant rods, sometimes called through-tool coolant rods, are cylindrical devices that are built into cutting tools including drills, end mills, and reamers. These rods include internal channels or tunnels that allow coolant (usually emulsions or compressed air) to flow directly to the cutting edge during machining operations. Coolant rods effectively dissipate heat, lubricate the cutting zone, and evacuate chips by providing coolant directly at the tool-workpiece interface, improving machining efficiency and tool life.