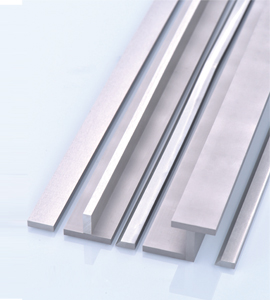

Cemented solid carbide rods provide the ideal combination of toughness and hardness, providing unparalleled performance in precision machining applications. These rods, which combine the resilience of cemented carbide with the hardness of solid carbide, are vital in industries that need precision, durability, and efficiency. This article looks at the composition, qualities, uses, and benefits of cemented solid carbide rods, providing light on their critical role in modern production.

Cemented solid carbide rods are made from a combination of tungsten carbide (WC) particles and a strong metal binder, usually cobalt (Co) or nickel. Tungsten carbide grains are bound together with the binder phase via a precise sintering technique, resulting in a strong and uniform structure. This mix of materials gives the rods remarkable hardness, wear resistance, and toughness, making them perfect for difficult machining jobs.